- Place of Origin:

-

Guangdong, China (Mainland)

- Brand Name:

-

Anconn

- Model Number:

-

398

- Item Name:

-

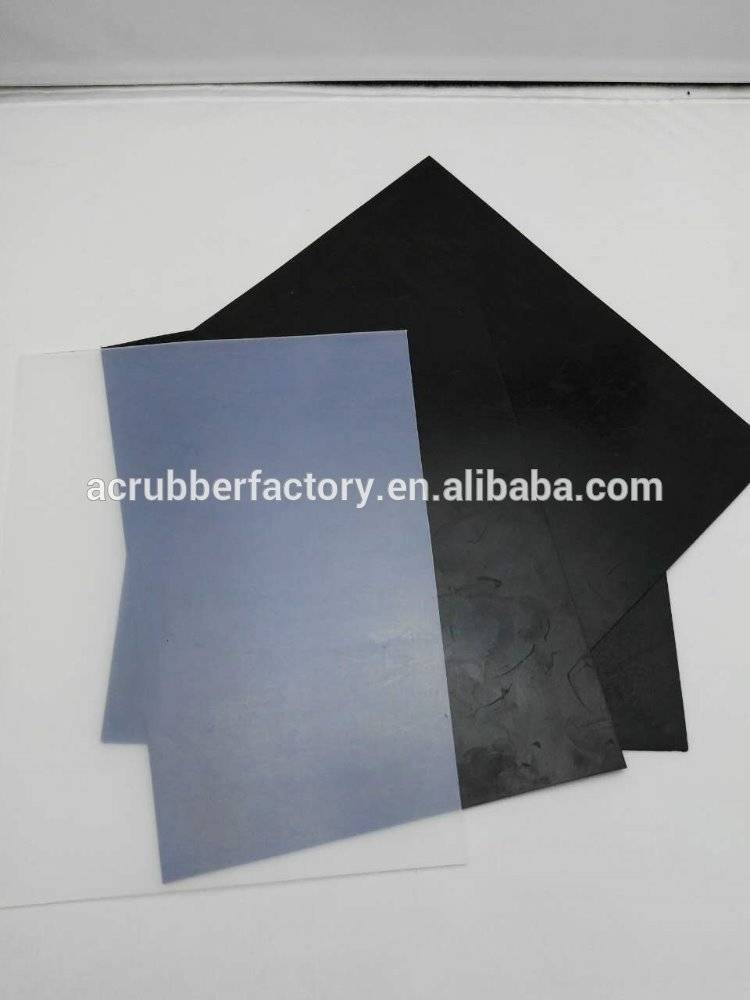

A4 rubber sheet

- Color:

-

black, clear or any other colors are available

- Material:

-

EPDM / NBR / Silicone / NR

- SIZE:

-

0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1 2 3 4 5 6 7 8 9 10 mm

- Usage:

-

floor or do other products

- Shape:

-

flat

- Function:

-

Waterproof, dustproof, airproof

- Hardness:

-

40 Shore A

- stock:

-

we have them in stock

- Certification:

-

ROHS

- Supply Ability:

- 1000000 Piece/Pieces per Week we can sell them to you at any quantity if we have them in stock

- Packaging Details

- 5,000 pcs/bag, 30,000pcs/CTN

- Port

- Shenzhen

- Lead Time :

-

Quantity(Pieces) 1 – 1000 >1000 Est. Time(days) 5 To be negotiated

0.5 0.8 1 1.5 2.0 2.5 3.0 mm 8.5×11 inch A4 silicone rubber sheet

| Part Name | A4 rubber sheet |

| Service | OEM OR ODM |

| Part Material | Silicone or rubber (NR, NBR,SBR,BR,IR,CR,EPDM,IIR,SIR,PU,ACM,CO,etc) |

| Material Hardness | Silicone about 20~80 Shore A; rubber about 30~90 Shore A |

| Size | Customized |

| Shape | Customized |

| Color | Customized according to Pantone colors |

| Appearance | as customer’s requirement |

| Drawings | 2D OR 3D acceptable |

| Temperature Resistance | -40~300 degree centigrade |

| Tolerance | 0.05mm |

| Technology | Hot pressing molding or injection Molding |

| Second Processing | Vulcanizing / Deburring / Silk-screen / Carving / printing |

| Quality control | internal QC control |

| Part Feature | 1.Oxidation , Chemical,oil, acid ,alkali , weather resistance |

| 2. colorful ,Anti-aging,good flexibility, good elasticity | |

| Food grade material | FDA or LFGB |

| MOQ: | Amount : More than USD 200/each part(depends on specific part) |

| Shipping ways | 1. By sea from Yantian port. 2. By express: DHL/UPS/FEDEX ,etc 3. By air |

| Package | Normally PE bag+carton or customized as customer’s request |

| Trade Term | Ex-works; FOB Shenzhen/Guangzhou ; CIF |

| Payment Term | Sample mold: 100% prepaid,MP Mould: 50% deposit by T/T in advance, balance 50% paid after samples approval |

| Goods: 50% deposit, 50% before shipment | |

| T/T, Western Union, PAYPAL | |

| Lead time | 5~10 days for making mold,7~15 days for mass production (depends on part structure ) |

| Specification | Confirm to ISO-9001 and ROHS Directive Compliant Green Products |

| Application field | 1. Electron components |

| 2. Medical equipment | |

| 3. Home appliance | |

| 4. Mechanical equipment | |

| 5. Office facilities | |

| 6. Aviation | |

| 7. Construction | |

| 8. Automobile |

Rubber Sheeting

We are able to offer various grades of rubber sheeting, these include:-

Neoprene

For general purpose gaskets and seals. Good UV resistance and moderate resistance to

oils and chemicals. Commercial grade 60°/70° sh. BS2752 grades from 40° to 70°.

Nitrile

Mainly used in an oil/fuel environment as it has excellent resistance. Commercial grade 60°/70° sh.

BS2751 40° to 70°

Natural

This material has excellent physical properties so is ideal for using as a seal in boats port

lights, hatches and doors. It has excellent abrasion resistance, so makes an ideal liner for shot blast

cabinets and material chutes. It is not resistant to oils. Hardness ranges from 40° to 70°

A food quality grade is available for marine fresh water tank seals.

Insertion

A natural rubber material with an insertion layer sandwiched in the middle of it to give it

strength, which helps prevent it tearing.

EPDM

This material has excellent resistance to UV, so is suitable for many outdoor applications. Commercial grade 60°/70°sh. A WRC grade is available for potable applications.

All of the above materials are available in ether full rolls, cut lengths, strip or gaskets.

Details and prices are available on application.

Our rubber sheet material is a general purpose industrial rubber used in any application needing a common elastic rubber material. Used in all kinds of instances from decorative to rubber sheeting flooring runners, industrial buildings, OEM parts, and other agricultural situations. This general purpose rubber sheet can be used almost anywhere that your applications need average rubber. This general purpose rubber has a longer wear life because it is press cured when manufactured.